Embracing a

sustainable future

Find more detailed information about the CCS program.

Contact us if you want more information, we will be happy to help you.

CELSA Circular Steel

Over recent years we have made significant progress towards our vision of making steel truly circular. Now, we are applying additional resources and focus with CELSA Circular Steel, a programme that will build on that progress by driving more value for our customers and partners, helping to meet their needs to increase sustainability and innovation.

CELSA Circular Steel brings together the activity and commitments across our entire Group that are accelerating the transition to fully circular steel. Much of that has deep roots in our history as a steel company that has upheld sustainable methods for more than 50 years. But this programme is not just about making CELSA more circular, it is about supporting and encouraging comprehensive and interconnected action across the entire steel value chain. This is not a project to deliver internal change, it is a long-term programme to achieve sector change.

We want to lead by example. We have set out to make this the connective tissue that drives more valuable change in the most effective ways. CELSA Circular Steel can help us all to achieve full circularity faster, through the contribution that this programme makes to Celsa’s ongoing commitment to circularity.

Goals

2030

-50% CO2 EQ. EMISSIONS*

2050

NET POSITIVE**

* Scope 1 + 2 Emissions, baseline year 2021

** Carbon Neutrality (scope 1 + 2 + 3), zero waste and zero accidents with a net positive impact on our planet

We have already taken giant steps

At the very heart of this is CELSA Circular Steel, our programme to make steel more sustainable, with a focus on circularity and emissions reduction. It is a programme that gives us ambitious goals, focusing on accelerating the drive to a net-positive future by closing the loop in everything we deliver. A strategic imperative that unites our Group at every level, and how we do business every day.

HIGH DEGREE OF TRACEABILITY

LEADER IN WASTE RECOVERY

100% RECYCLABLE

Infinite lives to finite resources

We are a large international group, but we ensure that in driving net-positive outcomes, we think and act locally.

Inspiring and delivering

sustained change

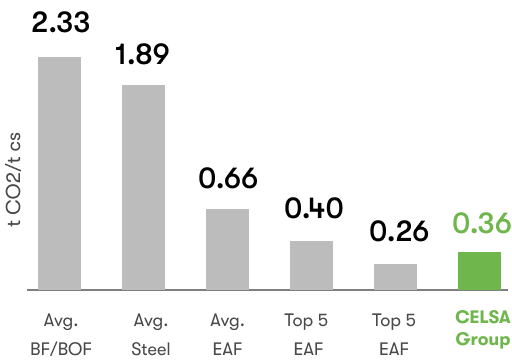

Our goal is clear: by 2030, we aim to reduce CO2 Scopes 1 and 2 emissions by 50%. We also intend to recover 98% of our waste by 2030 and have the ambition to become net-positive by 2050.

These are not lofty goals without substance – Celsa is acting now for the future, and we will measure our progress closely.

We have made significant progress. As we look ahead, we know there remains much to achieve, and that we must aim high.

Scope 1

Celsa’s most significant challenge – the continued use of fossil fuels – is also the most significant opportunity for advancement and impact. Innovation is helping us move the needle in reducing these emissions, for example by accelerating a green hydrogen value chain to replace fossil fuels in the production of rebar and wire rod.

Scope 2

We are working to reduce electricity consumption by improving energy efficiency and optimisation, particularly that used for Electric Arc Furnaces. And we are also ensuring that our electricity increasingly comes from renewable sources.

Scope 3

We will continue to implement sustainable procurement practices, which encourage collaboration with our supply chain, and in doing so reduce the embodied carbon of the goods and services we purchase.

We strive to make our planet a better place, not just today but for future generations.

Closing the loop together

CELSA Circular Steel draws together the elements of the value chain where action can have the greatest impact in the drive for circularity.

We have taken the lead on making steel circular. Now we are ready to accelerate our transformation to achieve a net-positive future by 2050, to give more back to society than we take.

As we do that, we will help others to come on the same journey. We will provide both a clear focus on change and ensure that each part of our ecosystem acts within the bigger picture of that transformation, with practical measurement of our progress. And to accelerate that, we have prioritised five pillars that will shape a more circular future.

The programme ‘nuts and bolts’

We are optimising everything already underway across our group to support our circular steel and sustainability objectives. Celsa can drive progress in alignment with our commercial priorities – particularly our sustainability strategy – to close the loop effectively.

New Product Offerings

CELSA Circular– a programme offering three differentiated products embedded in three strategic priorities.

The CELSA Circular Steel product offer is based on the three pillars, strengthening Celsa’s unique selling proposition and company values:

Customised increased recycled material content into our steel production process up to 100%:

• By taking advantage of our upstream-integrated business (selected raw materials, scrap management, local sourcing, etc.)

• By gaining full transparency / information of our whole supply chain, offering our customers to set more ambitious targets and challenges in terms of circularity (e.g. close loop processes).

Steel production processes with renewable electricity throughout certified guarantees of origin (clean energy = CO2 footprint up to 65% lower).

Carbon neutral steel complements the CELSA Circular Steel product offer by offsetting those unavoidable remaining emissions that Celsa is – as of today – not able to avoid and/or reduce.

Having offered low-carbon and circular steel for more than 50 years, we are continuing to achieve major milestones in carbon reduction through our products.

The greatest challenge of our time affects us and future generations. It is not only about reducing emissions – we believe that only by being circular can we fight climate change and tackle the depletion of natural resources.

Celsa is one of Europe’s largest steel producers and we strategically use our position to influence and inspire suppliers, customers, and other stakeholders. However, we can’t inspire without the participation of others, alongside active engagement.

We want our partners and customers to be co-creators. We don’t seek just passive members of an audience, but for active messengers for the product and the brand, so that they can spread our collective message.

We want stakeholders to be a part of something: to belong, to influence, to engage. It’s not enough that they feel good about our purpose – we want it to be their purpose too, to embrace it, because purpose needs to be shared.

And it is right here, in the will to have a shared purpose, where this pillar is born.

When we talk about partnerships, we mean a cooperation agreement under which two or more parties comply to unite their efforts or their resources to achieve this shared purpose.

Partnerships with suppliers will allow both parties to: launch strategies to fight climate change and the depletion of natural resources, ensure that we have traceability throughout our supply chain, and belong to the largest circular supply chain in Europe.

Conversely, coming into a partnership with CELSA Group, will enable customers to have availability of low carbon footprint products with full transparency and traceability, mitigating their scope 3 emissions.

Our partners can also co-create new products and features – allowing them to set more ambitious targets in terms of circularity – and to provide low carbon, circular and neutral solutions to their customers.

To create results, we must work together across industries, countries and areas of interest. Global challenges require collaboration on a global level in a cross-sectorial way. With customers, for example, we jointly develop new grades with higher scrap content to lower our carbon footprint. We also supply clean hydro/steel and partner on projects to increase circularity in the steel used for product manufacturing.

With our suppliers, we have developed a traceability and transparency circular project through advanced technologies (blockchain), with emissions, recyclability, quality and process data and certificates shared across the value chain.

Celsa is also one of the founders of the Global Steel Climate Council (GSCC). GSCC is an international coalition of steel producers and stakeholders committed to limiting global warming to 1.5 degrees Celsius by the year 2050 – its primary focus is to reduce emissions and establish high standards for the sector.

This pillar reinforces our active commitment to circularity and sustainability, and provides the highest degree of traceability to all stakeholders in our supply chain giving them certainty that the products and services they are sourcing from Celsa are contributing to a closed loop, circular supply chain.

Traceability and transparency go hand-in-hand, and at Celsa we understand the value that is generated in doing so, from improved business quality control to increased sustainability. Whilst this makes business sense, we understand that our customers also benefit from increased visibility of their supply chain and traceability allows them to do just that: track every aspect of manufacturing and distribution of products, from ‘cradle to grave’.

We have been working with customers to provide bespoke solutions that address the challenge of traceability within their supply chain. Across Celsa, we have introduced traceability labels. The label assures customers that the products we supply are 100% recyclable and produced with 100% recovered steel scrap, reducing their environmental footprints.

Upstream of our manufacturing process, the recovery and treatment of scrap provides Celsa with a strategic advantage when it comes to traceability. Not only are we able to get to the source of our primary raw material, scrap, but in doing so, we improve the quality of material recycled in our process. The benefits are two-fold: we are able to provide assurance to suppliers of scrap that the material they deliver to us will be processed and recycled in our Electric Arc Furnaces and for our customers, tailor steel products for them depending on scrap types (pre versus post-consumer scrap). One clear example is FERIMET, Spain’s leading recycler of iron scrap, which developed a third-party verified certificate based on three key circularity indicators: recyclability, traceability and proximity of the scrap to site.

Value has already been created for our stakeholders through our internal third-party certifications. And we are working in parallel to achieve external certifications that ensure compliance with globally recognised requirements, providing traceability throughout our supply chain. Over the next year, we will work with ISCC Plus, a sustainability certification programme for circular, recycled raw materials, focused on the traceability of raw materials in the supply chain.

We will be working closely with our innovation team to develop and implement the use of block chain technologies’ to create digital product passports. This will allow us to gather information about a product across its supply chain, improving our supply chains understanding of the products and its environmental impact.

Celsa’s approach to sustained investment, strengthened by being a business that can maintain long-term commitments, is to target innovation in production and processes while supporting the wider ecosystem internally and externally.

We want the amount we invest to have lasting benefit on multiple levels, diversifying our business activity, and generating sustainable growth and value for all.

Our investments are targeted at both the actions we can take to reduce our emissions and at long term improvements that will see an increase in circularity across our sector.

For Scope 1 emissions, the main area of focus is to reduce our consumption of natural gas. This will be achieved through increased use of oxyfuel combustion across our production process. Our investments will also include the future use of hydrogen along with other low carbon technologies. The premise of exploring other low carbon technologies beyond hydrogen is to future-proof the business against the existing short-term challenges that hydrogen presents. Our transition away from natural gas must be cost-competitive, so we see our long term future being a mix of green hydrogen, biofuels and the use of induction-based furnaces.

For Scope 2, lowering our electricity consumption and using more renewable sources is our primary focus. Celsa will invest in different areas, including equipment to improve the quality of the raw material, optimisation of EAF set-up and process, and improved efficiency of the grid and a range of data analytics to optimise use of furnaces.

Our actions across Scope 3 prioritise procurement practices and processes, which will not only decrease emissions but improve our relationships across our supply chain.

To further drive circular value chains we will invest in increasing our collection capacity through new scrap yards with a larger processing and waste segregation capacity. This will increase our ability to produce new products that can be used as raw material in other processes, such as plastics and other metals. In parallel, multiple smaller investments will be introduced in data, sensor applications, and automation in order to improve material traceability across the value chain.

Celsa innovation is driven by our sustainability strategy, with circularity, digitalisation and collaboration at its core.

As we lead the move to the blend of humans and advanced technology that will define industry 5.0, and so give added impetus to sustainability and people, our innovation will not just focus on what we produce but on the kind of world we want to build and the legacy we want to leave behind.

Focusing on our most significant challenges and opportunities, we innovate to reduce reliance on fossil fuels and primary raw materials, whilst developing – and sharing – market leading technologies to reduce emissions and increase the circularity of our value chains.

We are committed to continual engagement in several major European projects that are revolutionising industry. The EU is investing in innovation to support the green transition, especially in our sector. Through the Clean Steel Partnership for instance, the European Commission is unlocking €1.4 billion of public funding by 2027 for decarbonising steel. Beyond specific projects, Celsa plays an active role in many international industry networks, boosting innovation for sustainability through partnerships including the Association for Sustainable Process Industry (A.SPIRE), the European Clean Hydrogen Partnership and the European Raw Materials Alliance.

Our innovation efforts are critical to address multifaceted challenges industry is facing, ranging from global geopolitical issues to the accessibility of crucial raw materials such as scrap. By adopting a flexible and zero emission production approach applying a set of resource recovery and digitalisation tools, Celsa is well-positioned to achieve its sustainability and circularity objectives in the face of any future uncertainty. Moreover, through this commitment, Celsa supports others in reducing their environmental footprint and promoting a responsible use of raw materials.

We are also seeking to explore disruptive collaboration approaches to strengthen industry in its fight against climate change. Our efforts to innovate have brought together different industries, universities and research institutions to unlock the full potential of artificial intelligence in fostering learning on process optimisation and resource efficiency, thus aligning growth with the EU’s Green Deal objectives.